Software

Design custom fixtures in less than 20 minutes.

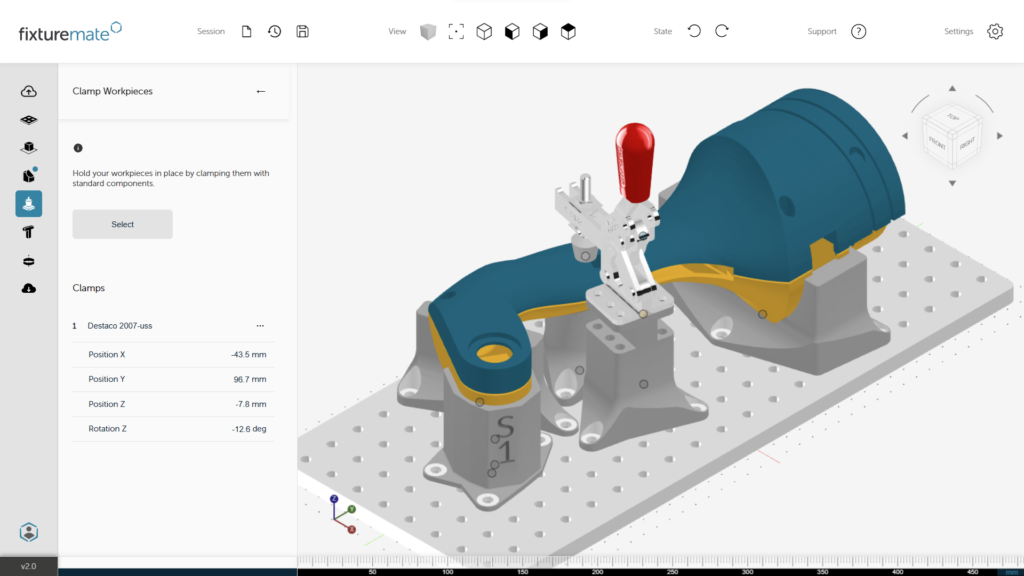

FixtureMate is an intuitive, web-based software for designing and configuring fixtures.

CAD knowledge is optional.

Design without CAD complexity

The manual design of fixtures is time-consuming—even for experienced engineers. fixturemate is an intuitive, web-based software that allows anyone to quickly design fixtures, regardless of whether they are familiar with CAD or not.

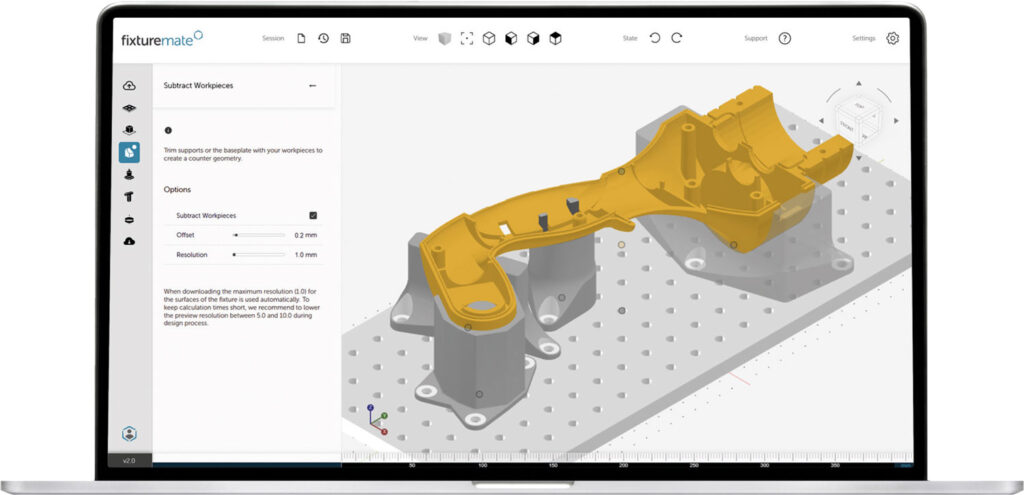

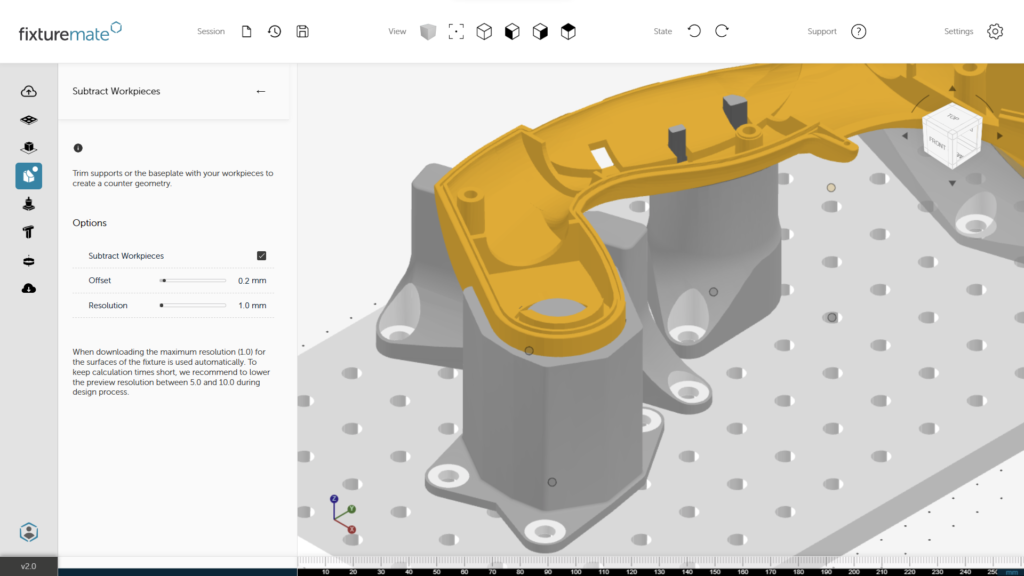

Simply create a negative

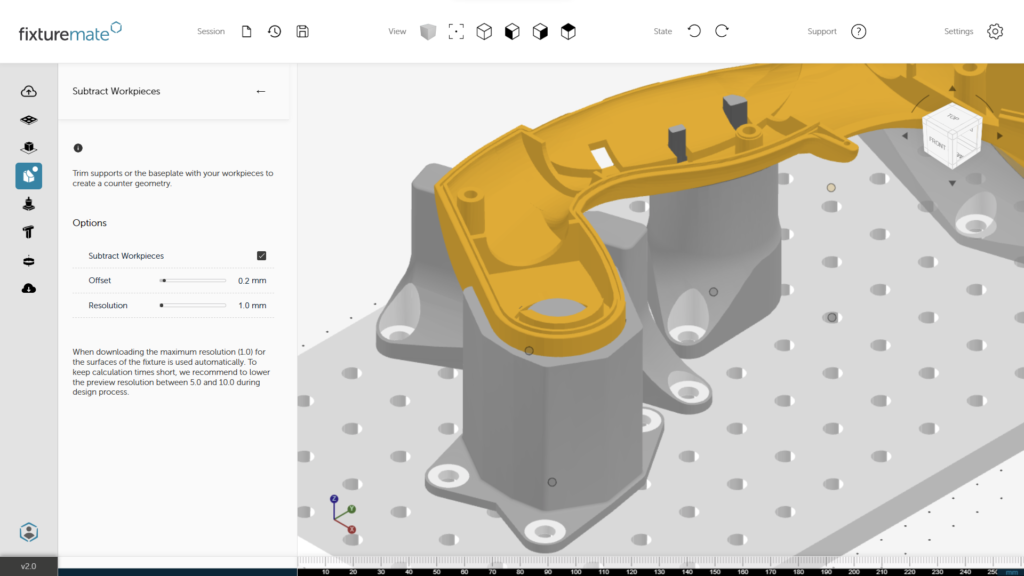

Subtract complex geometries in just a few clicks, avoid undercuts, and define tolerances—for a precise fixture.

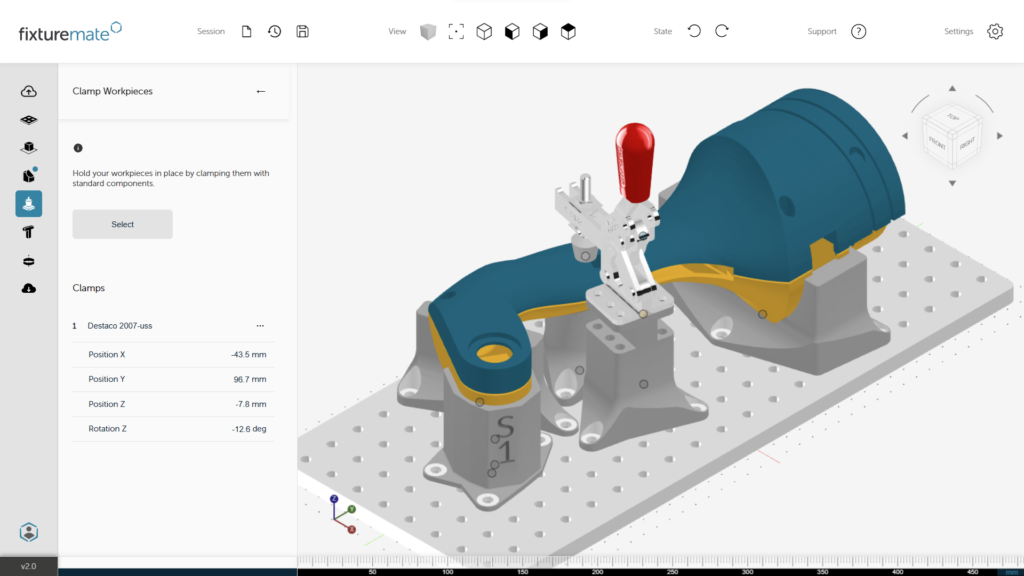

Industry-standard components included

A selection of standard clamps and base plates is available directly in fixturemate, saving you the effort of creating these components from scratch.

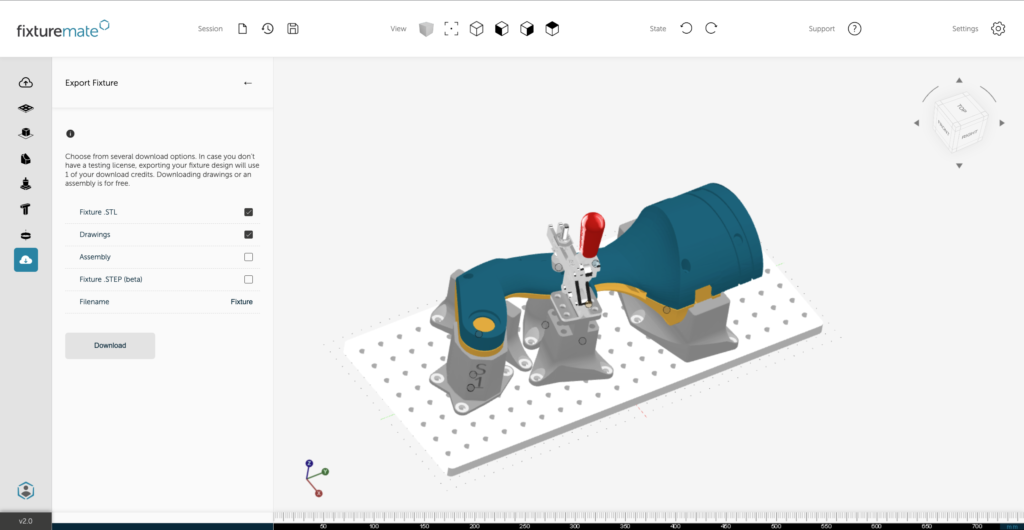

Seamless integration of 3D printing

Data exports are optimized for 3D printing, allowing you to easily slice, print, and deploy your custom fixture within hours.

One software, diverse applications

Assembly fixtures

Optimize assembly with precise part alignment for simplified assembly and fastening steps.

Measuring fixtures

Align components for CMM or CT quality control processes with minimal surface contact.

Machining fixtures

Create strong and stable custom workpiece clamps for turning, drilling, and milling operations.

Welding fixtures

Ensure precise alignment and stability during bonding and welding— for reliable repeatability.

Inspection Gauges

Use Go/No-Go inspection gauges to quickly check the accuracy of parts after production or assembly.

Workpiece and Load Carriers

Optimize internal logistics by efficiently and safely transporting delicate components between workstations.

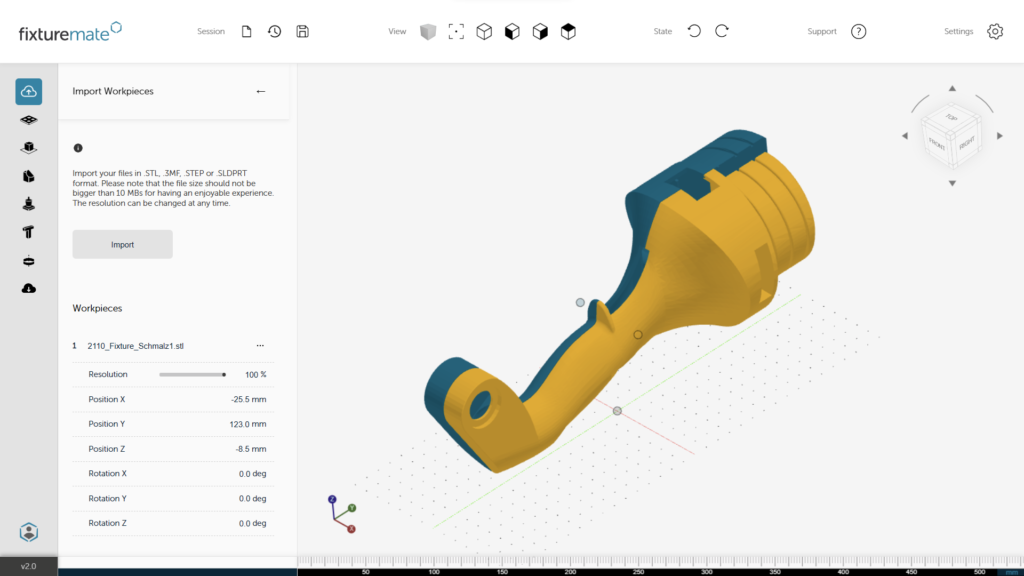

Upload STL, 3MF, SLDPRT, or STEP workpieces and position them in the working environment.

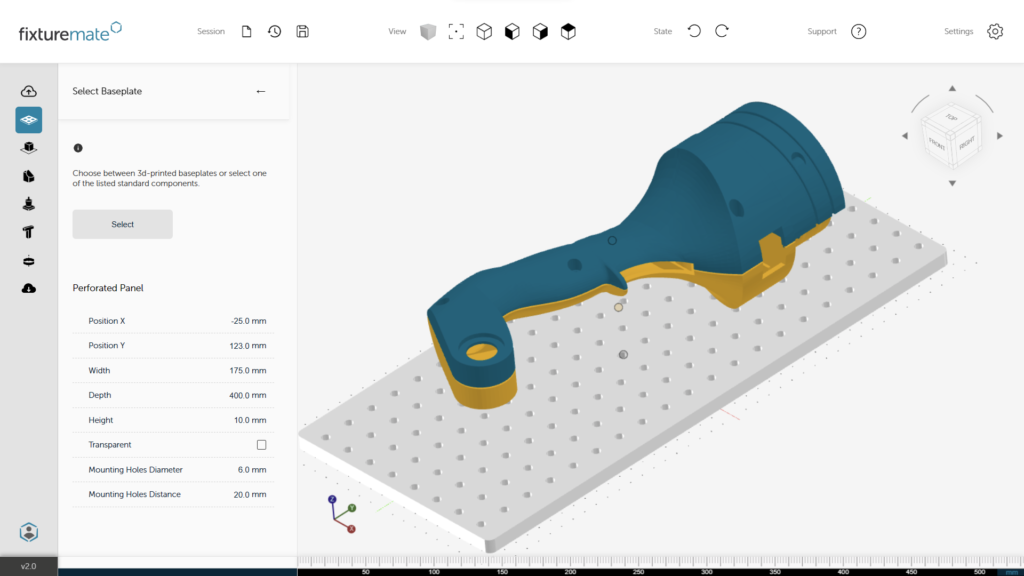

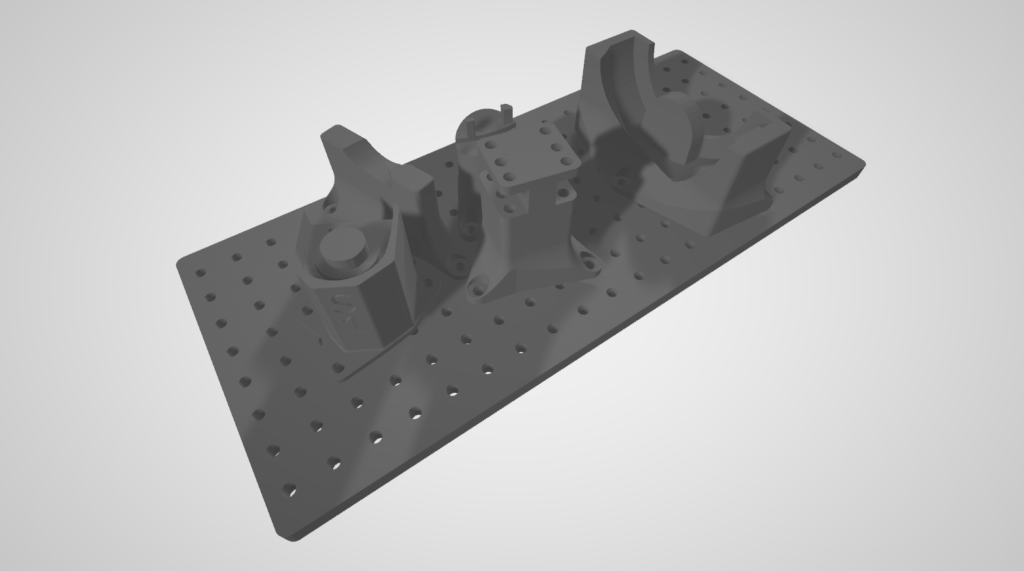

As the base plate of your fixture, you can choose between a standard component or a fully 3D-printed setup.

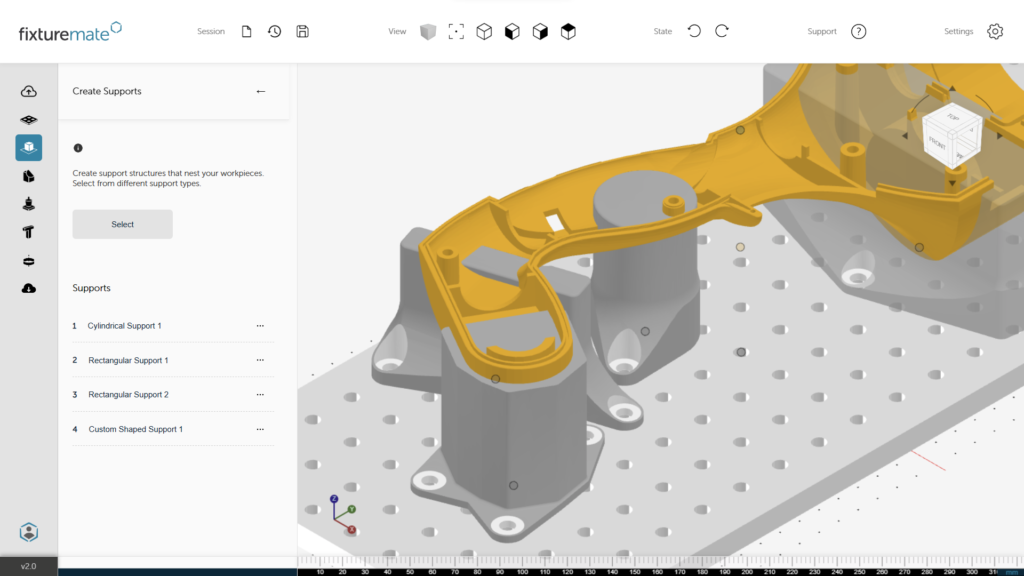

Support the workpiece with rectangular, cylindrical, conical, or custom structures.

Subtract your workpiece geometry from the support structures to obtain the negative and choose a precise offset for the desired fit accuracy.

Integrate optional elements such as clamps, labels, holes, or cutouts.

fixturemate outputs STL data optimized for 3D printing. It can also automatically create PDFs of 2D drawings to clearly document the assembly process.

Would you like to try fixturemate?

Would you like a personalized quote or further technical details?

Maybe you just want to discuss your design process and the possibilities for automation.

Whatever it is, please get in touch – we are happy to help you.