VX1 Vapor Smoothing Machine

Perfect surfaces for 3D-printed parts

Optimize your 3D-printed polymer components with the state-of-the-art VX1 vapor smoothing machine. This innovative technology offers a simple and effective method for smoothing and refining the surface texture of your additively manufactured parts without compromising detail accuracy.

Prototyping

Give your prototypes a high-quality surface that enhances their functionality and aesthetics.

End-use parts

Create smooth, ready-to-use end parts directly after printing.

Medical devices

Optimize surface quality for applications in medical technology.

Consumer goods

Produce appealing consumer goods with flawless surfaces.

Automotive industry

Smooth components for vehicles to enhance aesthetics and functionality.

Efficient handling with the VX1 vapor smoothing machine

In the VX1 vapor smoothing machine, the handling of the components is optimized for maximum efficiency and user-friendliness. After thorough cleaning and preparation, the components are securely hung with hooks. Once the frame is installed, the consumable cartridge is placed, and the process parameters are set, the process is initiated. Within 90 to 120 minutes, the entire smoothing process is completed, and the parts can be safely removed, ready for use or further processing steps.

90–120 minutes

Cycle time

Ø 28 x 40 cm

Process chamber

up to 80%

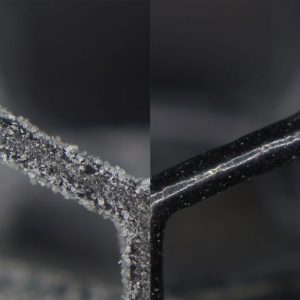

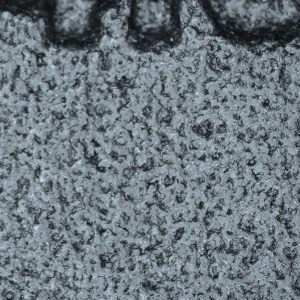

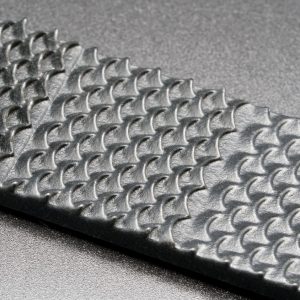

Reduction of surface roughness

What is vapor smoothing?

Vapor smoothing is a post-processing method for 3D-printed plastic parts. The components are exposed to a controlled vapor atmosphere that slightly melts and smooths the outer layer of the plastic. This results in a smooth, sealed surface that enhances resistance to external influences. Additionally, it improves the tightness against liquids and gases, optimizing the aesthetics and functionality of the printed parts. Unlike mechanical processing, vapor smoothing can also be applied to elastomers in addition to thermoplastics.

Efficient vapor smoothing

Gives your 3D-printed parts a professional, smooth surface.

Versatile material compatibility

Works with common powder materials PA12 and in the future TPU, PA11, and PP.

User-friendly interface

Intuitive touchscreen display for easy operation and monitoring of the smoothing process.

Fast process times

Significantly reduces post-processing time compared to manual methods.

Safety features

Equipped with advanced safety mechanisms for safe operation, including automatic shutdown and temperature control.

Compact design

Space-saving design that integrates seamlessly into any workshop or production environment.

The cartridge

The treatment agent is stored in cartridges that are inserted into the machine before the process begins. Each cartridge is specifically labeled for the material to be processed, and the machine automatically detects which material is to be processed. The use of cartridges allows for easy handling and quick material changes without additional retooling of the machine. The cartridges are part of a reusable system and are refilled by the manufacturer after use. This reduces waste and relieves the user of disposal responsibilities. This ensures an environmentally friendly and sustainable use while maximizing efficiency.

VX1 Vapor Smoothing Machine Webinar

To help you get up and running with your new 3D printer quickly, we offer you our quick start course in the form of a webinar (web-based seminar): After 120 minutes, you will understand how to use the 3D printing software.

Webinar Agenda

- Introduction to the functionality and operation of the 3D printing software

- Overview of the importance of settings

- The right settings for your perfect 3D print!

- Tips & Tricks

- Troubleshooting – Causes and solutions for common problems

Requirements

- Existing, ready-to-use PC with Windows 7, 8, or Mac OS X with full administrator rights

- Internet access

- Pre-installed and functional TeamViewer or Microsoft Teams software

The details of the appointment and the webinar software will be arranged after receiving your order.

Support and Service

- Professional consulting

- Sample print creation

- Custom packages for industrial clients

- On-site training

- Service package with free phone and email support

- Complete solution with wash station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Technical Specifications

| Abmessungen (W x D x H) | Deckel geschlossen: 450 × 660 × 1100 mm Deckel geöffnet: 450 × 660 × 1680 mm |

| Volumen der Prozesskammer (⌀ x H) | 280 × 400 mm (24.6 L) |

| Empfohlenes Prozessvolumen (W x D x H) | 180 × 220 × 340 mm (13.5 L) |

| Zykluszeit | 1.5 to 2 h |

| Leistungsanforderungen | 230 V AC, 12 A (dedizierte Schaltung) |

| Energieverbrauch | weniger als 1 kWh pro Zyklus |

| Kompatible Materialien | PA12 (PA11, TPU und PP in der Entwicklung) |

| Kompatible Druckverfahren | MJF, SLS, HSS, SAF |

| Klassifizierung der Behandlungsmittel | pharmazeutisch/lebensmittelgeeignet |