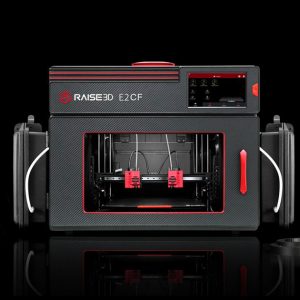

Raise 3D E2CF

Carbon fiber 3D printing made simple.

E2CF is a desktop 3D printer developed by Raise3D for carbon fiber-reinforced filaments and other composite materials.

Aerospace

Architecture

Automotive Industry

Commercial Good

Education

Medicine

Double-gear Extrusion System

The gears are made of high-hardness steel and have been heat-treated for higher resistance to wear.The gear tooth profile is customized, and the double gears engage tightly when operating so there is no filament slipping when extruding.The force of the double-gear is doubled to ensure the stability of printing.

1,75 mm

Filament Diameter

300°C

Extruder Temperature

30–150 mm/s

Print Speed

330 x 240 x 240 mm

Print Volume

Nozzle with High Durability

The silicon carbide nozzle has excellent thermal conductivity and resistance to wear, which will effectively lessen the abrasion the carbon fiber composite filament subjects the nozzle to when printing, making the nozzle more durable.

Compatible with a Variety of Carbon Fiber Composite Filaments

The E2CF is compatible with the Raise3D Industrial PA12 CF Filament, and is also very compatible with high-performance carbon fiber filaments certified by the Raise3D OFP program, such as PA / PPS / PETG and some other high-performance carbon fiber composite filaments from BASF and LEHVOSS.

Raise3D Filament Dry Box

The built-in detached double-disc suspension tray is used to place the filament to allow material to be pulled more smoothly. When closed, it can effectively prevent dust and moisture for up to 30 days*. *From Raise3D test data.

Exclusive ideaMaker Slicing Profiles

The E2CF has exclusive slicing profiles that have been repeatedly tested and verified by our engineers in ideaMaker. There is no need to adjust the parameters before printing. Enjoy easy and high-quality printing.

Raise 3D E2CF Webinar

To help you get up and running with your new 3D printer quickly, we offer you our quick start course in the form of a webinar (web-based seminar): After 120 minutes, you will understand how to use the 3D printing software.

Webinar Agenda

- Introduction to the functionality and operation of the 3D printing software

- Overview of the importance of settings

- The right settings for your perfect 3D print!

- Tips & Tricks

- Troubleshooting – Causes and solutions for common problems

Requirements

- Existing, ready-to-use PC with Windows 7, 8, or Mac OS X with full administrator rights

- Internet access

- Pre-installed and functional TeamViewer or Microsoft Teams software

The details of the appointment and the webinar software will be arranged after receiving your order.

Support and Service

- Professional consulting

- Sample print creation

- Custom packages for industrial clients

- On-site training

- Service package with free phone and email support

- Complete solution with wash station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Downloads

Technical Specifications

| Build Volume (WxDxH) | Single Extruder Print: 330×240×240 mm Dual Extruder Print: 295×240×240 mm |

| Machine Size (WxDxH) | 607×596×465 mm |

| Power Supply Input | 100-240 V AC, 50/60Hz 230 V @ 2A |

| Power Supply Output | 24 V DC, 350 W |

| Print Technology | FFF |

| Print Head System | IDEX Independent Dual Extruders |

| Filament Diameter | 1.75 mm |

| XYZ Step Size | 0.78125, 0.78125, 0.078125 micron |

| Print Head Travel Speed | 30 – 150 mm/s |

| Build Plate | Flexible Steel Plate with Buildtak |

| Max Build Plate Temperature | 110 ºC |

| Heated Bed Material | Silicone |

| Build Plate Leveling | Mesh-leveling with Flatness Detection |

| Filament Run-out Sensor | Available |

| Supported Materials | PA12 CF, PA12 CF Support, OFP Certified Third-Party Filaments |

| Layer Height | 0.1 – 0.25mm |

| Nozzle Diameter | 0.4 mm (Default), 0.6/ 0.8 mm (Available) |

| Hotend | V4P |

| Max Nozzle Temperature | 300 ºC |

| Connectivity | Wi-Fi, LAN, USB port, Live camera |

| Noise Emission (Acoustic) | <50 dB(A) when building |

| Operating Ambient Temperature | 15 – 30 °C, 10 – 90% RH non-condensing |

| Storage Temperature | -25 °C to +55 °C, 10 – 90% RH non-condensing |

| Filter | HEPA filter with activated charcoal |

| Slicing Software | ideaMaker |

| Supported File Types | STL/ OBJ/ 3MF/ OLTP |

| Supported OS | WINDOWS/ macOS/ LINUX |

| Machine Code Type | GCODE |

| User Interface | 7-inch Touch Screen |

| Network | Wi-Fi, Ethernet |

| Power Loss Recovery | Available |

| Screen Resolution | 1024*600 |

| Motion Controller | Atmel ARM Cortex-M4 120MHZ FPU |

| Logic Controller | NXP ARM Cortex-A9 Quard 1 GHz |

| Memory | 1 GB |

| Onboard Flash | 8 GB |