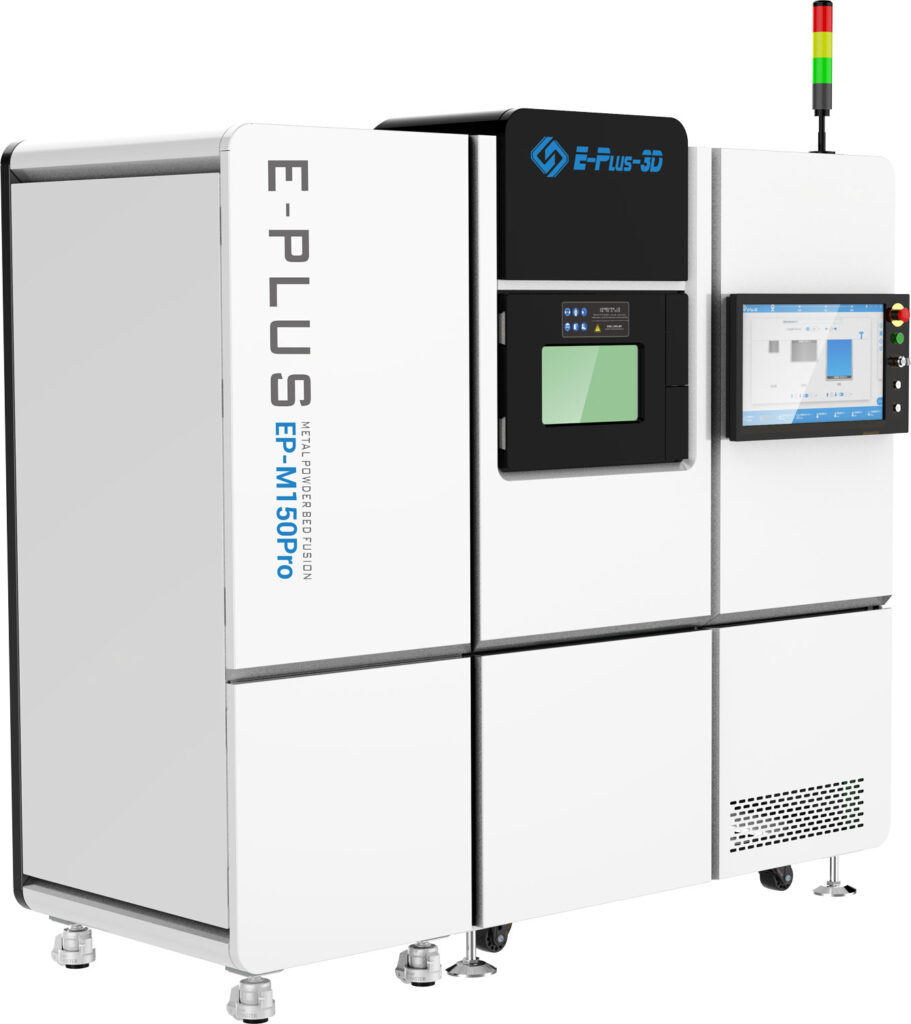

Eplus3D EP-M150 Pro

Metal Additive Manufacturing: high precision & fast

Medicine

Automotive Industry

Aerospace

Trade Goods

Energy

Architecture

Prototypes

High efficiency

With our latest technology, layer thicknesses of up to 100 μm are possible. Thanks to the use of dual lasers and high layer thicknesses, the output rate can be increased by an impressive 230 to 270%.

5 – 35 cm³/h

Build Speed

20 μm – 100 μm

Layer Thickness

Ø 156 x 240 mm³

Print Volume

High precision

High laser beam quality, small laser spot, and continuous and homogeneous laser beam quality at every position in the build space.

High performance

Achievable part density at > 99.95%, volatility of mechanical properties < 5%, and calibration accuracy in the laser overlap area with dual lasers < 30μm.

Openness

High repeatability and consistent parameter sets across multiple machines in the EP-M printer family. Compatible with multiple materials. The system can process different metal powders without adjusting the optical path.

User-friendly system

Ergonomic machine design. Thanks to the one-click printing function, the machine is ready to print in no time. The system can be prepared in just a few minutes.

Low Operating Costs

Inert gas consumption during the process < 3 L/min. Automated, controllable powder feed for high material efficiency. Existing material parameter sets are provided free of charge.

Safety

Fault-tolerant machine and software design. With appropriate filters and additional safety factors, operator safety is increased. Real-time monitoring of the process chamber and environment ensures a stable process and high reproducibility.

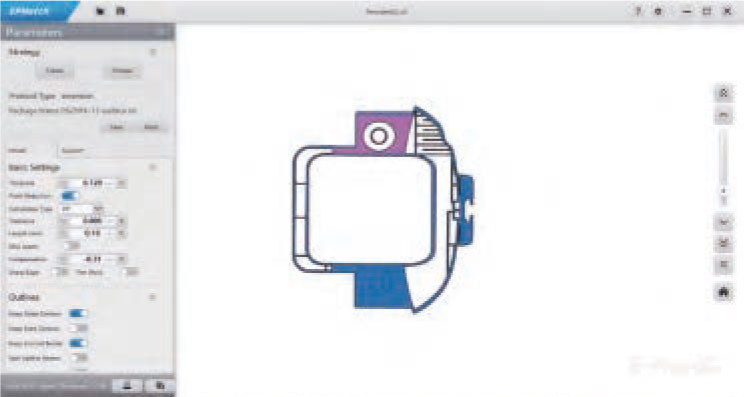

Eplus3D Software Solutions

EP-Hatch Print Process Planning Software

EP-Hatch is a process planning software developed by Eplus3D specifically for its additive manufacturing systems. It can optimize the print path based on the already sliced and output data and adjust the scan path separately for contour, interior, top, and bottom surfaces of the part. Additionally, EP-Hatch comes standard with a variety of advanced scan strategies such as long straight lines, short straight lines, and chessboard patterns, enabling optimal process settings for specific materials.

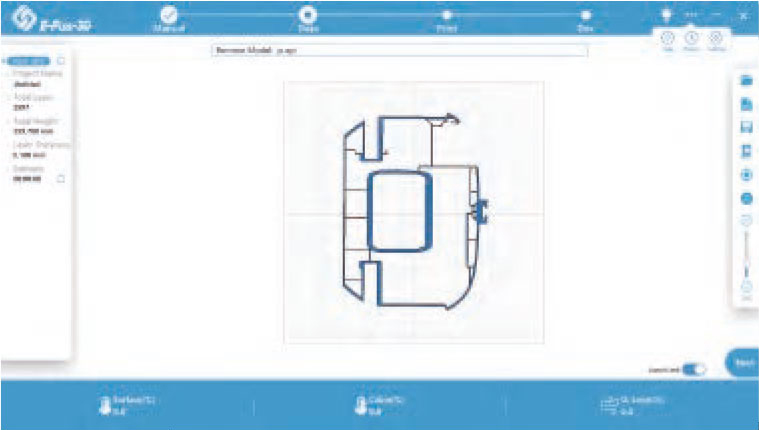

Eplus3D Control Software

The control software developed by Eplus3D represents a powerful control system. With an open and user-friendly interface, it allows users to easily manage their digital files from build preparation and part positioning and provides the ability to monitor during the build process along with reporting. The powerful control and operating system supports not only the printing of mature materials but also the development of new materials.

Eplus3D EP-M150 ProSupport and Service

- Professional consultation

- Sample print creation

- Customized packages for industrial clients

- On-site training

- Customized service packages

- Complete solution with closed depowdering station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Technical Specifications

| Maschinenmodell | EP-M150 Pro |

| Bauraum | Ø 156 x 240 mm³ |

| Optisches System | Faserlaser, 500 W (Single- oder Duallaser) |

| Laserspotgröße | 70 μm |

| Max. Scangeschwindigkeit | 8 m/s |

| Baugeschwindigkeit | Singlelaser: 5 – 20 cm³/h Duallaser: 8 – 35 cm³/h |

| Schichtdicke | 20 μm - 100 μm |

| Genauigkeit | Bis 100 mm Baugröße: < ±0,1 mm Ab 100 mm Baugröße: ± 0,1 % |

| Material | Titan-, Aluminium-, Nickelbasis, Cobalt-Chromlegierungen sowie Werkzeug- und Edelstähle, etc. |

| Stromversorgung | 380 V, 3P/N/PE, 12 KW, 23 A, 50~60 Hz (Duallaser: 13.5 KW, 28 A) |

| Gasversorgung | Ar/N2 |

| Sauerstoffgehalt in Prozesskammer | < 100 ppm |

| Dimensionen (L x B x H) | 2120 x 980 x 2250 mm³ |

| Gewicht | 1500 kg |

| Software | EP-Hatch, EP Control; weitere auf Anfrage |

| Format Eingangsdaten | STL oder andere konvertierbare Formate |