Eplus3D EP-S600

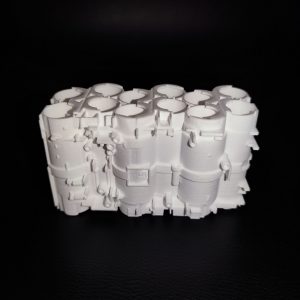

SLS printer specialized in orthotics

By using Polymer Powder Bed Fusion (PPBF) with a build cylinder of up to 420 x 380 x 600 mm, the EP-S600 ensures a combination of high printing efficiency, fast scanning speed, large build volume, and low operating costs. The EP-S600 fully meets the customization and production requirements of the rehabilitation and medical industry, enabling customized production.

Medicine

Automotive Industry

Aerospace

Trade Goods

Energy

Architecture

Prototypes

High Performance and Efficiency

The average print time of a single orthosis is 11 hours, so one machine can produce 400–450 orthoses per year. The advanced and fast optical system fits perfectly with the 55W CO2 laser and achieves a scanning speed of 7.8 m/s. The high material reuse rate and low waste amount effectively reduce material consumption.

11 hours

Print time of an orthosis

0,1 – 0,3 mm

Layer Thickness

420 x 380 x 600 mm

Print Volume

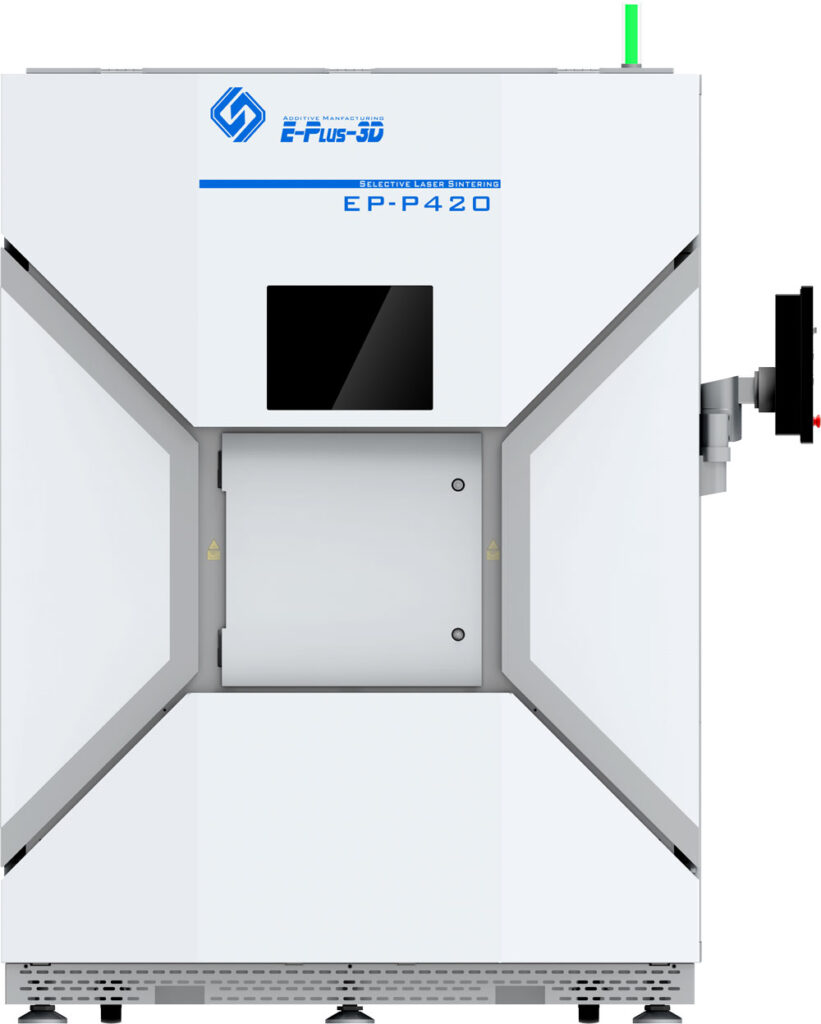

Advanced optical system

The advanced and fast optical system fits perfectly with the 55W CO2 laser and achieves a scanning speed of 7.8 m/s.

High Material Reuse Rate

High material reuse rate

Open Print Parameters

Open Print Parameters Enable the Development of New Materials.

Large Volume Powder Dispenser

One fill is enough for the entire cylinder print.

Removable protective windows

Removable optical protective windows facilitate daily maintenance.

Intelligent

A visualized printing process and automatically generated print reports enable tracking of the printing process.

User-Friendly

Ability to print with just one click and convenient remote control via smartphone.

Dust-free process

The process of removal and powder processing takes place in the cleaning platform.

Reliable filter

The gas in the build chamber is safely discharged through multi-stage filtration and adsorption.

Eplus3D Software Solutions

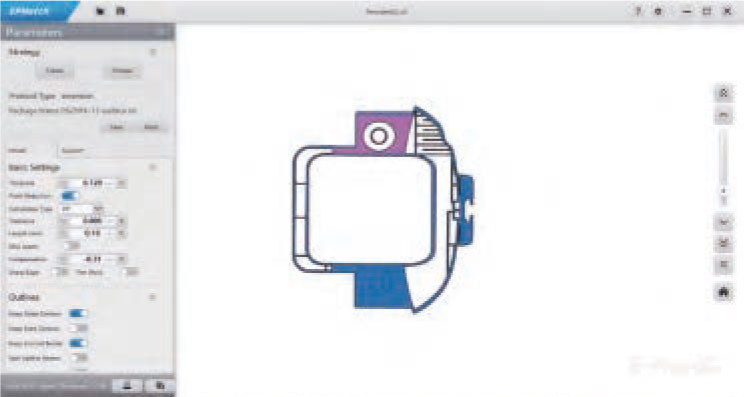

EP-Hatch Print Process Planning Software

EP-Hatch is a process planning software developed by Eplus3D specifically for its additive manufacturing systems. It can optimize the print path based on the already sliced and output data and adjust the scan path separately for contour, interior, top, and bottom surfaces of the part. Additionally, EP-Hatch comes standard with a variety of advanced scan strategies such as long straight lines, short straight lines, and chessboard patterns, enabling optimal process settings for specific materials.

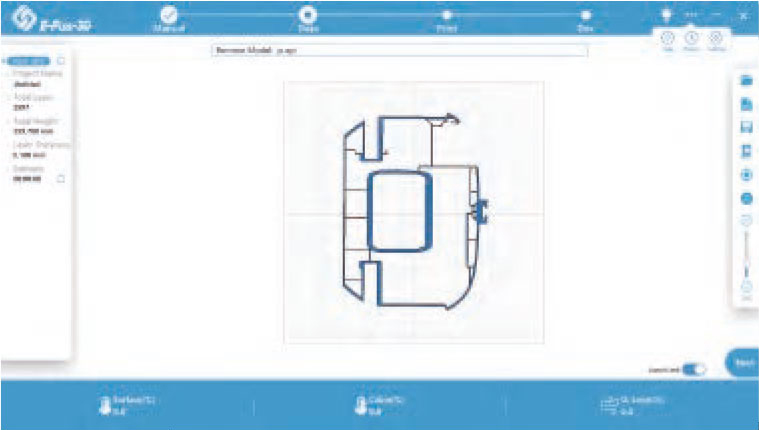

Eplus3D Control Software

The control software developed by Eplus3D represents a powerful control system. With an open and user-friendly interface, it allows users to easily manage their digital files from build preparation and part positioning and provides the ability to monitor during the build process along with reporting. The powerful control and operating system supports not only the printing of mature materials but also the development of new materials.

Eplus3D EP-S600Support and Service

- Professional consultation

- Sample print creation

- Customized packages for industrial clients

- On-site training

- Customized service packages

- Complete solution with closed depowdering station

- Component optimization via remote maintenance

- Material testing

- Process optimizations

- Custom seminars on-site

- On-site service

Downloads

Technical Specifications

| Maschinenmodell | EP-S600 |

| Größe der Baukammer | 420 x 380 x 600 mm (L×B×H) |

| Gerätedimension | 2480 x 1415 x 2160 mm (L×B×H) |

| Materialien | PP und dessen Verbundwerkstoffe |

| Maschinengewicht | 1.600 kg |

| Scan-Geschwindigkeit | Max. 7.8 m/s |

| Max. Kammertemperatur | 260 °C 220 |

| Stromversorgung | 220 V, 1/N/PE, 50/60 Hz |

| Schichtdicke | 0,1 – 0,3 mm |

| Laserleistung | 55 W CO2 Laser, 120 W |

| Betriebssystemunterstützung | Windows 7/ Windows 10 |

| Thermische Feldsteuerung | Unabhängiges Vierzonen-Temperaturregelungssystem |

| Temperaturregelung | Kontinuierliche Echtzeitüberwachung der Bautemperatur |

| Steuersoftware | Eplus3D Drucksoftware |

| Ausgabedatenformat | STL, OBJ, STEP oder andere konvertierbare Datei |