Formlabs Fuse 1+ 30W

3D-Druck in Rekordgeschwindigkeit

Dank eines neuen, leistungsstärkeren 30-Watt-Lasers und verbesserter Pulverhandhabung erreicht der Fuse 1+ 30W eine durchgehend hohe Druckteilqualität bei Rekordgeschwindigkeit.

Medizin

Audio

Dental

Schmuck

Architektur

Prototypen

Verlässlicher, einheitlicher Druck

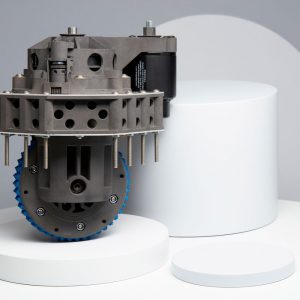

Maximaler Durchsatz bei minimalem Abfall: Der Fuse 1+ 30W ist unser kompakter SLS-3D-Drucker, der selbst Fertigung auf Industrieniveau stemmt.

0,5 Liter pro Stunde

Druckgeschwindigkeit (20% Packdichte)

110μm

Schichtdicke

165 x 165 x 300 mm

Fertigungsvolumen

Bis zu doppelt so schnell wie sein Vorgänger

Der 3D-Drucker verfügt über ein verbessertes Galvanometersystem und bietet eine schnellere Scan-Geschwindigkeit von bis zu 12,5 Metern pro Sekunde. Der Fuse 1+ 30W ist auf einen effizienten End-to-End-Workflow sowie Zuverlässigkeit ausgelegt. Neue Komponenten sollen den Durchsatz und die Materialleistung verbessern.

Die Maschine arbeitet als kompaktes und geschlossenes Ökosystem und von der Druckeinrichtung bis zur Pulverrückgewinnung und -Mischung maximiert laut Formlabs die 3D-Drucker-Hardware und die Formlabs-Software die Effizienz in jedem Prozessschritt. Statt in vielen Tagen druckt der Fuse 1+ 30W hochleistungsfähige Teile in Stunden.

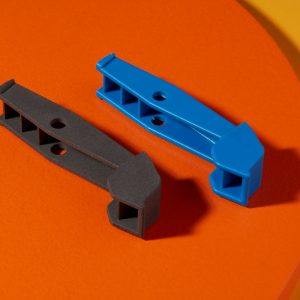

Neu: Nylon 11 CF Powder

Nylon 11 CF Powder ist ein auf Nylon basierendes, karbonfaserverstärktes Pulver, mit dem Anwender stabile und leichte Teile herstellen können, die wiederholten Stößen standhalten. Dadurch eignet es sich für Ersatzteile und Alternativen von Metallteilen, hochbelastbare Geräte und funktionale Prototypen aus Verbundwerkstoffen.

Nylon 11 CF Powder eignet sich hervorragend für:

- Austausch- und Ersatzteile für Metallkomponenten

- Werkzeuge, Halterungen und Vorrichtungen

- Stoßfeste Geräte

- Funktionale Komponenten aus Verbundwerkstoffen

Nylon 12

Das eingesetzte Material, Nylon 12, ermöglicht die Produktion vollständig funktionaler Prototypen oder Funktionsteile, mit hervorragenden mechanischen und thermischen Eigenschaften.

- Mit 11% Bruchdehnung bricht Nylon im gebogenen Zustand nicht, sondern kehrt wieder in seine ursprüngliche Form zurück.

- Mit 50 MPa Zugfestigkeit ist Nylon 12 beständig gegenüber Zugbeanspruchung und perfekt für strukturelle, tragende oder mechanische Teile.

- Nylon ist hitzebeständig und eignet sich für Hochtemperatur-Anwendungen und Teile, die thermisch stabil sein müssen.

- andere Materialien befindet sich derzeit in der Entwicklung.

Überragende Druckgeschwindigkeit

Erhalten Sie hochpräzise Teile innerhalb von 24 Stunden dank eines leistungsstarken 30-Watt-Lasers, der mit einer Abtastgeschwindigkeit von bis zu 12,5 Metern pro Sekunde druckt.

Materialien in Industriequalität

Nutzen Sie exklusive neue Materialien und erzielen Sie höhere Leistungen mit den bisherigen, durch die aktive Pulverhandhabung und die Option des Drucks in Inertgasatmosphäre.

Weniger Abfälle, hoher ROI

Dank der optimierten Packdichte und Wiederverwertbarkeit des Pulvers ist uns eine echte Meisterleistung gelungen: abfallfreier 3D-Druck, und damit verringerte Stückkosten.

Verlässlicher, einheitlicher Druck

Beim SLS-3D-Druck wird Pulver Schicht für Schicht gesintert. Das ungenutzte Pulver stützt die Teile während des Drucks, sodass Sie komplexe, verbundene Designs drucken können, ohne dass Stützstrukturen benötigt werden.

Pulverrückgewinnung als Komplettlösung

Unsere Universalstation Fuse Sift kombiniert Teileentnahme, Pulverrückgewinnung, -lagerung und -mischung in einem einzigen Gerät

Geschaffen für ununterbrochenen Durchsatz

Erreichen Sie rekordschnelle Druckgeschwindigkeiten, mit denen Sie Prototypen und Kleinserien von Endverbrauchsteilen in unter 24 Stunden herstellen.

Materialien für Formlabs Fuse 1+ 30W

TPU 90A Powder

Formlabs Fuse 1+ 30W Webinar

Damit Sie mit Ihrem neuen 3D-Drucker schnell produktiv arbeiten können, bieten wir Ihnen unseren Schnellstart-Kurs in Form eines Webinars (Web-basiertes Seminar) an: Nach 120 Minuten verstehen Sie die Funktionsweise der 3D-Drucksoftware.

Ablauf des Webinars

- Einführung in die Funktionsweise und Bedienung der 3D-Drucksoftware

- Überblick über die Bedeutung der Einstellungen

- Die richtigen Einstellungen für Ihren perfekten 3D Ausdruck!

- Tipps & Tricks

- Trouble Shooting – Ursachen und Lösungen für die häufigsten Probleme

Voraussetzungen

- Vorhandener, einsatzbereiter PC mit Windows 7, 8 oder Mac OS X mit vollen Administrator-Rechten

- Internetzugang

- Bereits installierte und funktionsbereite TeamViewer oder Microsoft Teams Software

Die Details zum Termin und der Webinar-Software werden nach Eingang Ihrer Bestellung abgesprochen.

Support und Service

- Professionelle Beratung

- Musterdruck Erstellung

- Individuelle Pakete für Industriekunden

- Einschulung vor Ort

- Servicepaket mit kostenlosem Telefon- und Email Support

- Gesamtlösung mit Waschstation

- Bauteiloptimierung via Fernwartung

- Materialversuche

- Prozessoptimierungen

- Kundenspezifische Seminare vor Ort

- Vor Ort Service

Downloads

Technische Daten

| Modell | Fuse 1+ 30W |

| Technology | Selektives Lasersintern (SLS) |

| Fertigungsvolumen (B × T × H) | 165 x 165 x 300 mm |

| Schichtdicke | 110 Mikrometer |

| Druckgeschwindigkeit (20% Packdichte) | 0,5 Liter / Stunde |

| Lasertyp | Ytterbium-Faser |

| Schichtstärke (Achsauflösung) | *110 Mikrometer |

| Laserspotgröße (FWHM) | 247 Mikrometer |

| Materialneuzuführungsrate | 30–50 % |

| Einfülltrichterkapazität | 14,5 Liter |

| Stützstrukturen | Keine Stützstrukturen |

| Mindestabmessungen für den Zugang (B × T × H) | 125,5 × 149,5 × 187 cm |

| Druckerabmessungen (B × T × H) | 64,5 × 68,5 × 107 cm (165,5 cm mit Ständer) |

| Gewicht | 120 kg (ohne Konstruktionskammer oder Pulver) |

| Anlaufzeit | 60 Minuten |

| Umgebungsbedingungen | 18–28 ºC ≤ 50 % Luftfeuchtigkeit |

| Betriebstemperatur | 200 ºC |

| Temperaturregelung | Quarz-Heizelemente Resistiver Lufterhitzer |

| Lüftung | Schnittstelle zur Inertgaszufuhr Druckgesteuerte zweistufige Filtration (Auswechselbare HEPA- und Aktivkohlefilter) |

| Energiebedarf | EU: 230 V Wechselstrom, 7,5 A (eigener Stromkreis) USA: 120 V Wechselstrom, 15 A (eigener Stromkreis) |

| Galvanometer | Sonderausführung von Formlabs, 2. Generation |

| Laserspezifikationen | Ytterbium-Faser zertifiziert nach DIN EN 60825-1:2014 Wellenlänge 1070 nm Maximal 30 Watt Strahldivergenz von 3,24 mrad (Nennwert, Full-Angle) |

| Konnektivität | WLAN (2,4/5 GHz), Ethernet (1000 Mbit), USB 2.0 |

| Druckersteuerung | Interaktiver Touchscreen (10,1”) Auflösung 1280 × 800 |

| Benachrichtigungen | Benachrichtigungen und Verfolgung über Touchscreen SMS/E-Mail über Dashboard Live-Video mit Computer Vision Proaktive Wartungsbenachrichtigungen |

| Konnektivität | WLAN (2,4 GHz) Ethernet (1000 Mbit) USB 2.0 |

| Dateitypen | STL oder OBJ Ausgabe als FORM-Datei |