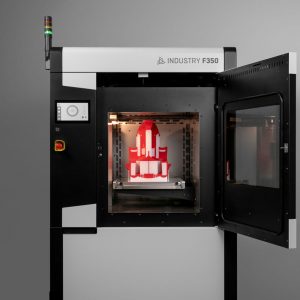

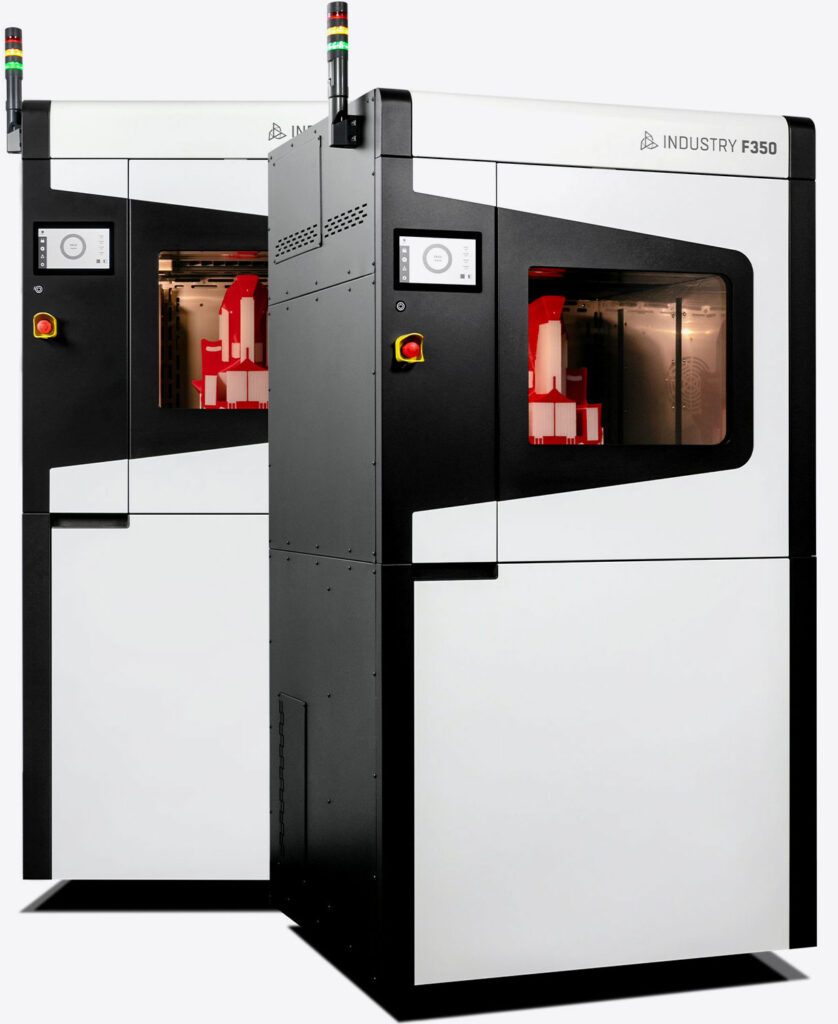

3DGence Industry F350

Entwickelt für industrielle Anwendungen.

Luft- & Raumfahrt

Architektur

Automobilindustrie

Handelsgüter

Bildungswesen

Medizin

einzigartige Geschwindigkeit

Erzielen Sie die besten Ergebnisse mit einzigartiger Geschwindigkeit des Industry F350 Druckers. Durch den Einsatz von im geschlossenen System arbeitenden Schrittmotoren wird die beste Druckqualität bei hoher Druckgeschwindigkeit und hoher Geschwindigkeit der Einstellbewegungen erzielt. Druckgeschwindigkeit bis 400 mm/s und 1 m je Sekunde für Einstellbewegungen des Druckers.

50 μm

Schichtauflösung

bis 500°C

Extruder Temperatur

bis zu 400 mm/s

Druckgeschwindigkeit

340 x 340 x 350 mm

Druckvolumen

M280

bis 280°C

Arbeitstemperatur

0,5 mm

Düsendurchmesser

Druckmaterial

PLA

ABS

ASA

PA6

PA-CF

Stützmaterial

ESM-10

HIPS

M360

bis 360°C

Arbeitstemperatur

0,4 mm

Düsendurchmesser

Druckmaterial

PC

Stützmaterial

ESM-10

M500

bis 500°C

Arbeitstemperatur

0,4 mm

Düsendurchmesser

Druckmaterial

PEEK

Stützmaterial

ESM-10

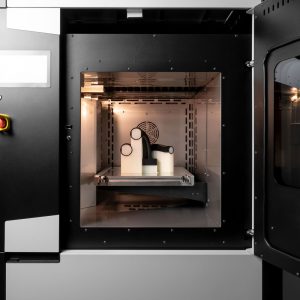

Beheizbare Druckkammer

Der Industry F350 Drucker ist mit einer aktiv beheizbaren Arbeitskammer ausgestattet, die für optimale 3D-Druckbedingungen sorgt. Die Kombination von der beheizbaren Druckkammer, passender Extrusionstemperatur sowie der beheizbaren Filamentkammer erlaubt die möglichst beste Qualität der Druckerzeugnisse aus hochbeständigen Materialien wie PEEK oder PC zu erzielen. Die aktiv beheizbare für optimale Temperaturbedingungen sorgende Kammer erlaubt die Druckprozesse aus Polycarbonat und Copolymeren auf PC-Basis und erzielt die mechanischen Nenneigenschaften des Materials, ohne das Modell aufzurollen. Dabei können auch etwaige Fehler der gedruckten Teile eliminiert werden.

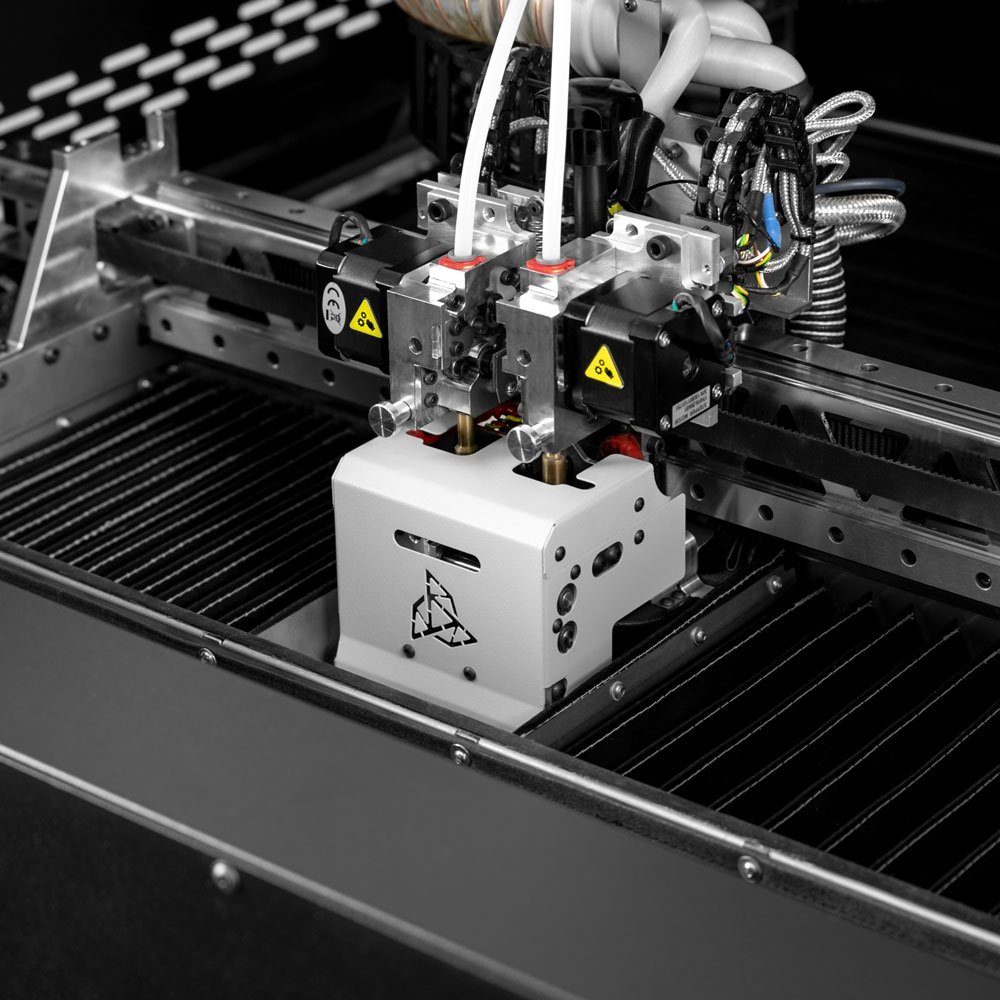

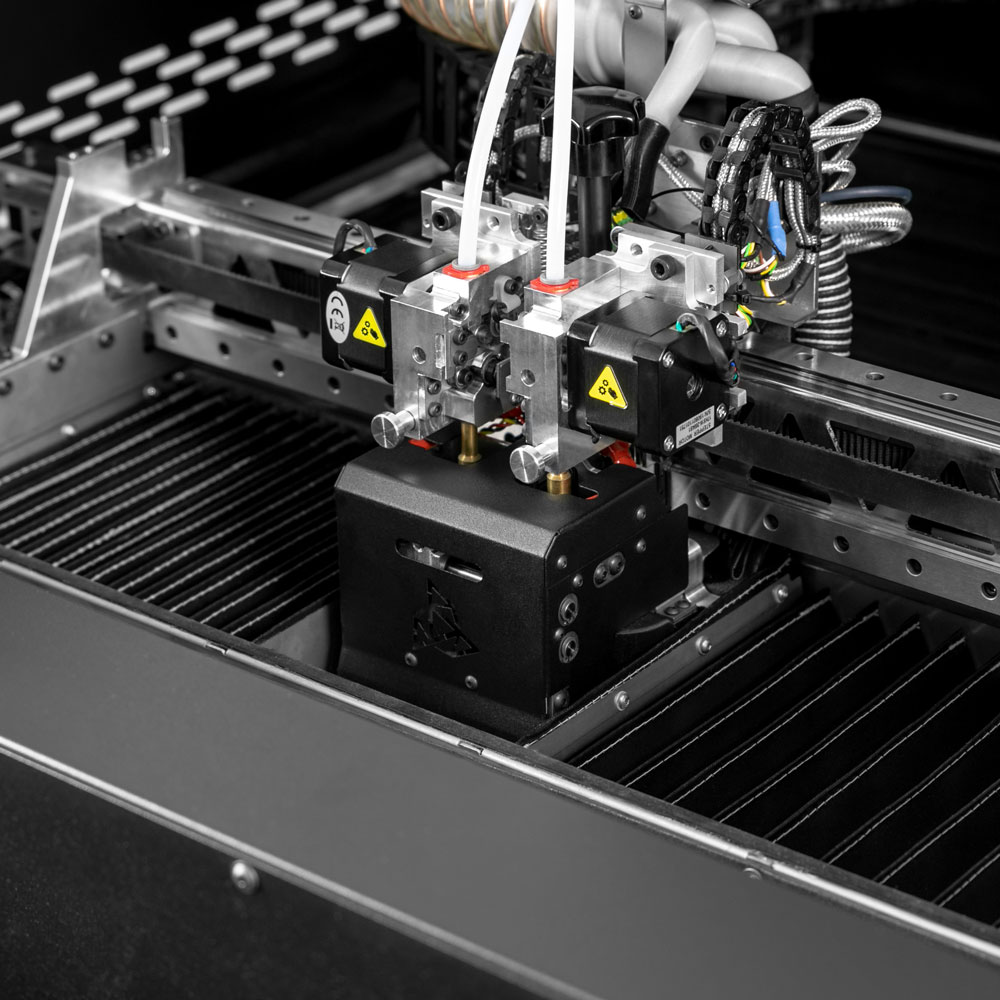

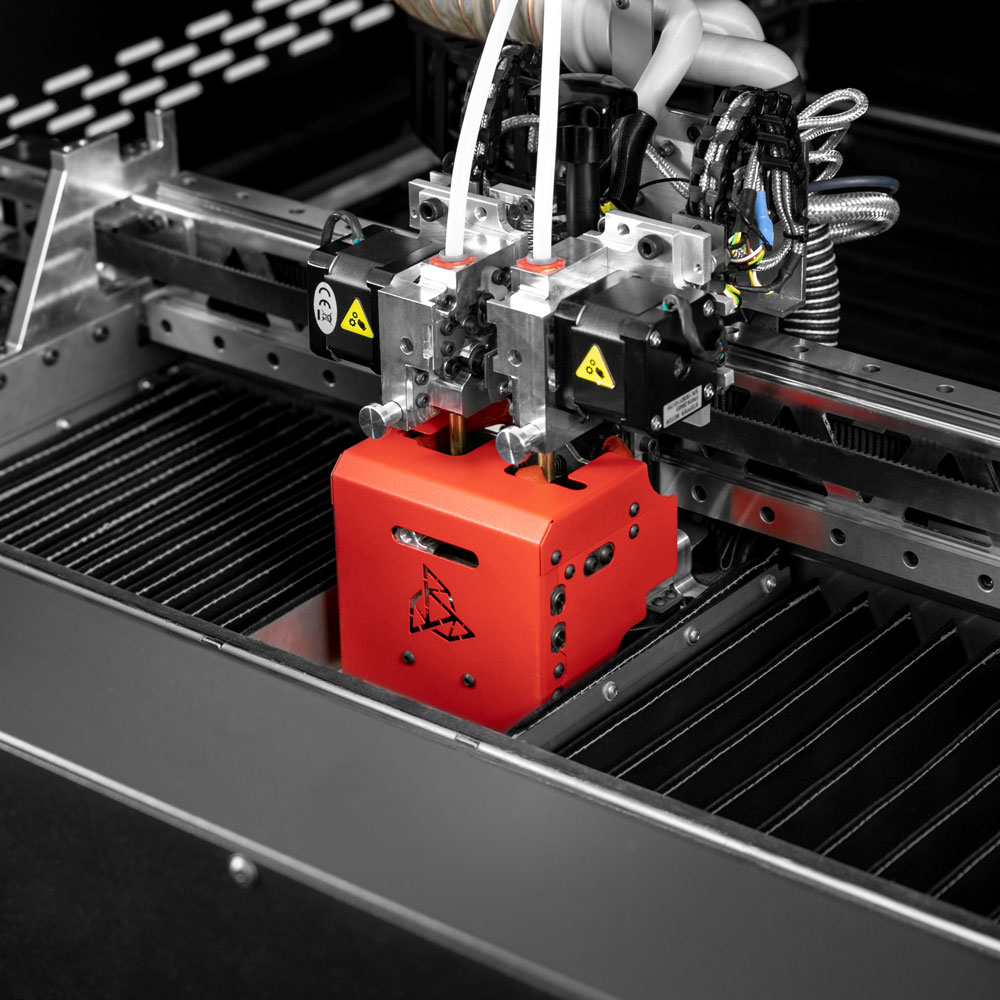

Vielseitigkeit

Drucken Sie aus mehreren hochbeständigen und ingenieurtechnischen Materialien an einem Gerät. Es können drei austauschbare Module an einem 3D-Drucker verwendet werden, was die Produktion von reproduzierbaren Modellen aus einer Vielzahl von Materialien erlaubt. Die Module sind austauschbar auch zwischen Industry F350 und Industry F420. Aktuelles Materialportfolio des Druckers Industry F350: PEEK, PA6, PA-CF, PC, ABS, ASA sowie PLA.

Langfristige Wirtschaftlichkeit

3D-Industriedrucker mit niedrigsten Betriebskosten (TCO) in seiner Klasse.

Lernen Sie die Vorteile des 3D-Drucksystems mit dem besten Preis-Druckkammervolumen-Verhältnis im Bereich der Industriedrucker kennen. Sparen Sie Zeit und Geld innerhalb der gesamten Betriebszeit des Industry F350 Industriedruckers.

Materialien für 3DGence Industry F350

PA6 Low Warp CF15S™

3DGence Industry F350 Webinar

Damit Sie mit Ihrem neuen 3D-Drucker schnell produktiv arbeiten können, bieten wir Ihnen unseren Schnellstart-Kurs in Form eines Webinars (Web-basiertes Seminar) an: Nach 120 Minuten verstehen Sie die Funktionsweise der 3D-Drucksoftware.

Ablauf des Webinars

- Einführung in die Funktionsweise und Bedienung der 3D-Drucksoftware

- Überblick über die Bedeutung der Einstellungen

- Die richtigen Einstellungen für Ihren perfekten 3D Ausdruck!

- Tipps & Tricks

- Trouble Shooting – Ursachen und Lösungen für die häufigsten Probleme

Voraussetzungen

- Vorhandener, einsatzbereiter PC mit Windows 7, 8 oder Mac OS X mit vollen Administrator-Rechten

- Internetzugang

- Bereits installierte und funktionsbereite TeamViewer oder Microsoft Teams Software

Die Details zum Termin und der Webinar-Software werden nach Eingang Ihrer Bestellung abgesprochen.

Support und Service

- Professionelle Beratung

- Musterdruck Erstellung

- Individuelle Pakete für Industriekunden

- Einschulung vor Ort

- Servicepaket mit kostenlosem Telefon- und Email Support

- Gesamtlösung mit Waschstation

- Bauteiloptimierung via Fernwartung

- Materialversuche

- Prozessoptimierungen

- Kundenspezifische Seminare vor Ort

- Vor Ort Service

Technische Daten

| 3D-Drucktechnologie | FFF |

| Arbeitsraum | 340 x 340 x 350 mm (40 460 cm3) |

| Schichtauflösung (min.) | 50 μm |

| Anzahl der Druckköpfe | Doppelextruder ausgestattet mit Reinigungssystem |

| Düsendurchmesser | 0.5/0.5 mm, 0.4/0.4mm |

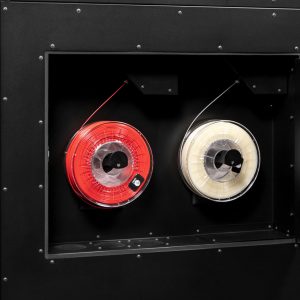

| Durchmesser des Filamentes | 1.75 mm |

| Temperatur des Druckkopfes (max.) | 500°C |

| Temperatur des Druckbettes (max.) | 160°C |

| Temperatur der Arbeitskammer (max.) | 130°C (aktive Heizung) |

| Filament chamber temperature (max) | 50°C |

| Leerlaufbewegungen | 1000 mm/s |

| Druckgeschwindigkeit | bis zu 400 mm/s |

| Drucker | 1825 x 960 x 940 mm |

| Gewicht des Druckers | 335 kg |

| Gehäuse | Stahl |

| außen | Stahl, Kammer mit Edelstahl ausgekleidet |

| Bauoberfläche | Borosilikatglas / vakuumversiegelte Kunststoffplatten |

| Positionierungsgenauigkeit XY Achse | 0.006 mm |

| Positionierungsgenauigkeit Z Achse | 0.0007 mm |

| Betriebstemperatur | 18-30°C |

| Lagerungstemperatur | -20-54°C |

| Erforderlicher Anschluss | – 230V 1ph 16A, CEE 7/7 Stecker – 2 x 120V 180° Schnittstelle, NEMA 6I-20P 20A Stecker (USA) |

| Max. Stromaufnahme | 3300 W |

| Kommunikation | ethernet, Wi-Fi, USB |

| Drucksoftware | 3DGence SLICER 4.0 |

| Cloud-basierte Dienste | 3DGence CLOUD |

| Filter | Fortgeschrittene ULT-Filtrationseinheit |

| Sensoren | Türöffnungssensoren, Oberdeckelöffnungssensoren, Temperatursensoren, NOT-Schalter |

| UPS – Notstromversorgung | ja, optional |